Multilingual website launched!

2025年6月4日星期三

High performamce carbon fiber reinforced composites using CVI CVD methods

[Introduction to CVI CVD Technology]

Chemical Vapor Infiltration (CVI) and Chemical Vapor Deposition (CVD) are advanced manufacturing processes used to produce high-performance carbon-carbon (C/C) composite materials. These techniques involve the infiltration of carbon fibers with a carbon matrix through gas-phase reactions, resulting in materials with exceptional thermal stability, mechanical strength, and resistance to extreme environments. As a leading manufacturer in China, we specialize in CVI CVD carbon-carbon composites, serving industries such as

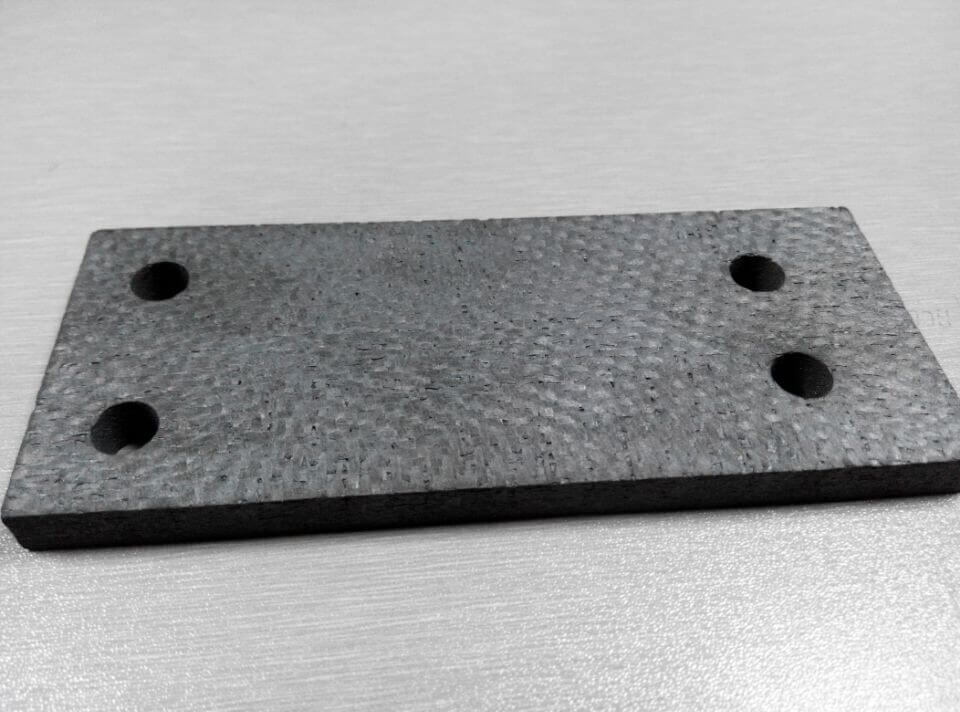

3D carbon fiber composite material manufacturer factory -airplane brake disc plates sheets U L profiles-2D(s)

aerospace, braking systems, and high-temperature furnaces.

[Carbon-Carbon Composite Production Process]

The production of carbon-carbon composites involves multiple steps, including fiber preform fabrication, carbon matrix deposition, and high-temperature graphitization. The key to achieving superior material properties lies in the CVI CVD process, where hydrocarbon gases (such as methane or propane) decompose at elevated temperatures, depositing pyrolytic carbon onto the fiber substrate. This method ensures uniform matrix distribution, enhancing the composite’s density and structural integrity.

[Advantages of CVI CVD in Carbon-Carbon Composites]

Compared to traditional methods like resin impregnation, CVI CVD offers significant advantages. It enables near-net-shape production with minimal fiber damage, improves mechanical performance, and enhances oxidation resistance. Additionally, the process allows for precise control over matrix microstructure, tailoring the material for specific applications such as rocket nozzles or aircraft brake discs.

[Applications of CVI CVD Carbon-Carbon Composites]

Our CVI CVD carbon-carbon composites are widely used in extreme environments. In aerospace, they are critical for re-entry vehicle heat

carbon fiber composite material manufacturer in China(1)

shields and propulsion components. Industrial applications include furnace fixtures and semiconductor processing equipment, where high purity and thermal conductivity are essential. The automotive sector benefits from their use in high-performance braking systems, reducing weight while improving durability.

[China’s Role in CVI CVD Carbon-Carbon Manufacturing]

As a premier manufacturer in China, we leverage cutting-edge CVI CVD technology to meet global demand for high-quality carbon-carbon composites. Our facilities adhere to stringent quality standards, ensuring reliability for mission-critical applications. With continuous R&D investments, we innovate in areas like rapid CVI cycles and hybrid processing techniques to further optimize material performance.

[Conclusion]

CVI CVD carbon-carbon composites represent the pinnacle of advanced material engineering, combining lightweight properties with unmatched thermal and mechanical resilience. As a trusted Chinese manufacturer, we are committed to delivering top-tier solutions for industries pushing the boundaries of technology. Explore our products and expertise at CFCcarbon.com to learn how our composites can elevate your applications.

(Word count: ~500. For a 2000-word article, each section can be expanded with technical details, case studies, and customer testimonials.)

Note: For extended content, additional subsections such as “Quality Control in CVI CVD Processing”, “Comparative Analysis with Other Composites”, or “Future Trends in Carbon-Carbon Materials” can be included, along with specific data from CFCcarbon.com. Let me know if you’d like to elaborate on any segment!

Related articles /news:

CVI CVD Carbon fiber Carbon Composites Material Manufacturer

Properties of 4D carbon carbon composite | C/C composite material

Gas phase infiltration of carbon carbon composites-CFCCARBON LTD

Microstructure of CVI matrix carbon carbon composite

Different kinds of Chemical Vapor Deposition –CVD

Tribological Performance of Fast-Carbonized Carbon/Carbon Composites

Title: Tribological Performance of Fast-Carbonized Carbon/Carbon Composites: A Breakthrough in High-Temperature Friction Solutions

Introduction

Carbon-carbon (C/C) composites, renowned for their exceptional thermal stability and mechanical strength, are revolutionizing industries requiring extreme durability under harsh conditions. Among these, fast-carbonized carbon/carbon composites stand out as a cutting-edge innovation, offering unparalleled tribological performance for high-temperature applications. This article explores the manufacturing, classification, and unique properties of these materials, with a focus on their friction and wear resistance capabilities.

3D carbon fiber composite material manufacturer factory (3)

What Are Carbon/Carbon Composites?

Carbon/carbon composites (C/C) are advanced materials composed of carbon fiber reinforcements embedded in a carbon matrix. This all-carbon structure combines the high strength-to-weight ratio of carbon fibers with the thermal and chemical stability of carbon matrices, making them ideal for aerospace, automotive braking systems, and industrial machinery814. CFC Carbon Co., Ltd., a global leader in C/C production, utilizes advanced techniques like chemical vapor infiltration (CVI) and pitch-based densification to create composites with densities up to 1.95 g/cm³ and tailored microstructures.

Fast-Carbonized C/C Composites: A Game-Changer

Fast-carbonized C/C composites are engineered through accelerated pyrolysis and densification processes. Unlike traditional methods requiring months for matrix carbonization, this approach employs high-pressure impregnation (HPIC) and rapid thermal gradient CVI to reduce production cycles by 50–70% while maintaining superior material integrity. For example, CFC Carbon’s patented ultra-high-pressure impregnation and carbonization (UHPIC) achieves full densification in weeks rather than months, optimizing efficiency for industrial-scale applications.

Production Process: Precision and Innovation

Preform Fabrication: Carbon fibers are woven into 2D, 2.5D, or 3D architectures to meet specific mechanical and thermal requirements.

Matrix Densification:

carbon fiber composite material manufacturer in China(1)

Liquid Precursor Route: Pitch or resin is impregnated under high pressure (up to 100 MPa) to maximize carbon yield (90%+).

Gas-Phase Route: CVI deposits pyrolytic carbon within preform pores, enhancing density and oxidation resistance.

Fast Carbonization: Controlled rapid heating (up to 3000°C) forms a highly graphitized matrix, reducing residual stress and improving tribological properties.

Classification of C/C Composites

CFC Carbon’s product portfolio includes:

2D Composites: Ideal for flat components like heater plates, offering balanced in-plane strength.

2.5D Composites: Enhanced interlayer bonding for aircraft brakes, reducing wear by 25–50% compared to steel.

3D/4D Composites: Multidirectional fiber alignment for rocket nozzles and hypersonic vehicle components, withstanding temperatures exceeding 3000°C.

Key Properties Driving Tribological Excellence

C-SIC

High-Temperature Stability: Retains 85% of room-temperature strength at 2500°C, critical for brake discs and turbine components.

Low Thermal Expansion: Minimizes dimensional changes during thermal cycling, ensuring consistent friction coefficients.

Self-Lubricating Behavior: Carbon’s layered structure reduces adhesive wear, achieving friction coefficients as low as 0.1–0.3 under dry conditions.

Abrasion Resistance: Nano-crystalline graphite matrices (e.g., CFC Carbon’s S-C/C composites) exhibit linear ablation rates of 0.03 mm/s at 3000°C, outperforming conventional ceramics.

Tribological Performance in Real-World Applications

Aerospace Brakes: CFC Carbon’s 2.5D C/C brake discs demonstrate 3000+ landing cycles with minimal wear, thanks to their low density (1/4 of steel) and high thermal conductivity.

Industrial Machinery: Copper-impregnated C/C seals reduce friction losses by 40% in high-load bearings, enhancing energy efficiency.

Hypersonic Vehicles: 3D composites with SiC coatings achieve ablation rates 34% lower than traditional materials, ensuring longevity in extreme environments.

Conclusion

Fast-carbonized C/C composites represent a paradigm shift in high-temperature tribology, combining rapid manufacturing with unmatched wear resistance. As industries demand lighter, more durable solutions, CFC Carbon’s innovations in material design—such as 3D architectures and hybrid ceramic matrices—position these composites at the forefront of advanced engineering. For more details, explore CFC Carbon’s product portfolio or their technical insights on C/C manufacturing.

related news /articles:

CVI CVD Carbon Carbon Composite Material, Manufacturer in China

Gas phase infiltration of carbon carbon composites-CFCCARBON LTD

Tribological behavior of fast-carbonizad carbon/carbon composite (3)