3D 4D CFC carbon fiber composite preform-preforming-Prefab (1)

2025年5月13日星期二

2.5D needle punch CFC airplane Brake disc-carbon fiber composite preform-preforming-Prefab T700 12K (3)

2.5D needle punch CFC airplane Brake disc-carbon fiber composite preform-preforming-Prefab T700 12K (3)

2025年5月9日星期五

High-Performance CFCs Molds: Revolutionizing Industrial Manufacturing

1. What Are Carbon Fiber Composites?

Carbon fiber composites (CFCs) are advanced materials combining carbon fibers with high-temperature matrices like resin or carbon-carbon

Low & high pressure carbon fiber composite mould-CC-CFC (1)

(C/C). These composites exhibit exceptional strength-to-weight ratios, thermal stability (up to 3,000°C in inert environments), and corrosion resistance. According to CFC Carbon’s technical guide, C/C composites are engineered by reinforcing carbon fibers with pyrolytic carbon, making them ideal for extreme conditions.

2. Optimal Material for Molds: Why 2D-Wound C/C Composites Dominate

When selecting mold materials for high-stress applications, 2D-wound carbon-carbon composites outperform traditional metals and graphite. Key advantages include:

Higher Fiber Volume (60-70%): Enhanced mechanical strength and wear resistance.

Superior Thermal Conductivity: Even heat distribution reduces warping during processes like hot pressing.

Extended Lifespan: 5-10x longer durability than graphite molds under cyclic thermal loads.

3. Types of C/C Molds: Specifications & Performance Comparison

high performance carbon fiber composite mould-2D structure-material manufacturer China

CFC Carbon offers three industrial-grade C/C mold categories:

| Type | Max Temperature | Size Range | Key Features |

|---|---|---|---|

| Standard 2D | 2,200°C | 100mm–2m diameter | Cost-effective, high oxidation resistance |

| High-Density 3D | 2,800°C | Customizable | Ultra-low CTE, ideal for aerospace components |

| Quick-Cycle | 1,800°C | <500mm diameter | Rapid heating/cooling, 30% faster production |

Pricing starts at $800 for standard molds, with custom designs tailored to client specifications.

4. Primary Applications of CFC Molds

CFC Carbon’s molds are widely adopted in critical industries:

Hot Pressing Machines: For sintering advanced ceramics (e.g., silicon nitride, zirconia).

Industrial Ceramics: Manufacturing wear-resistant seals, cutting tools, and electronic substrates.

Aerospace: Producing turbine blades and rocket nozzles requiring zero thermal deformation.

Automotive: Lightweight brake discs and EV battery components.

5. Technical Advantages Over Traditional Materials

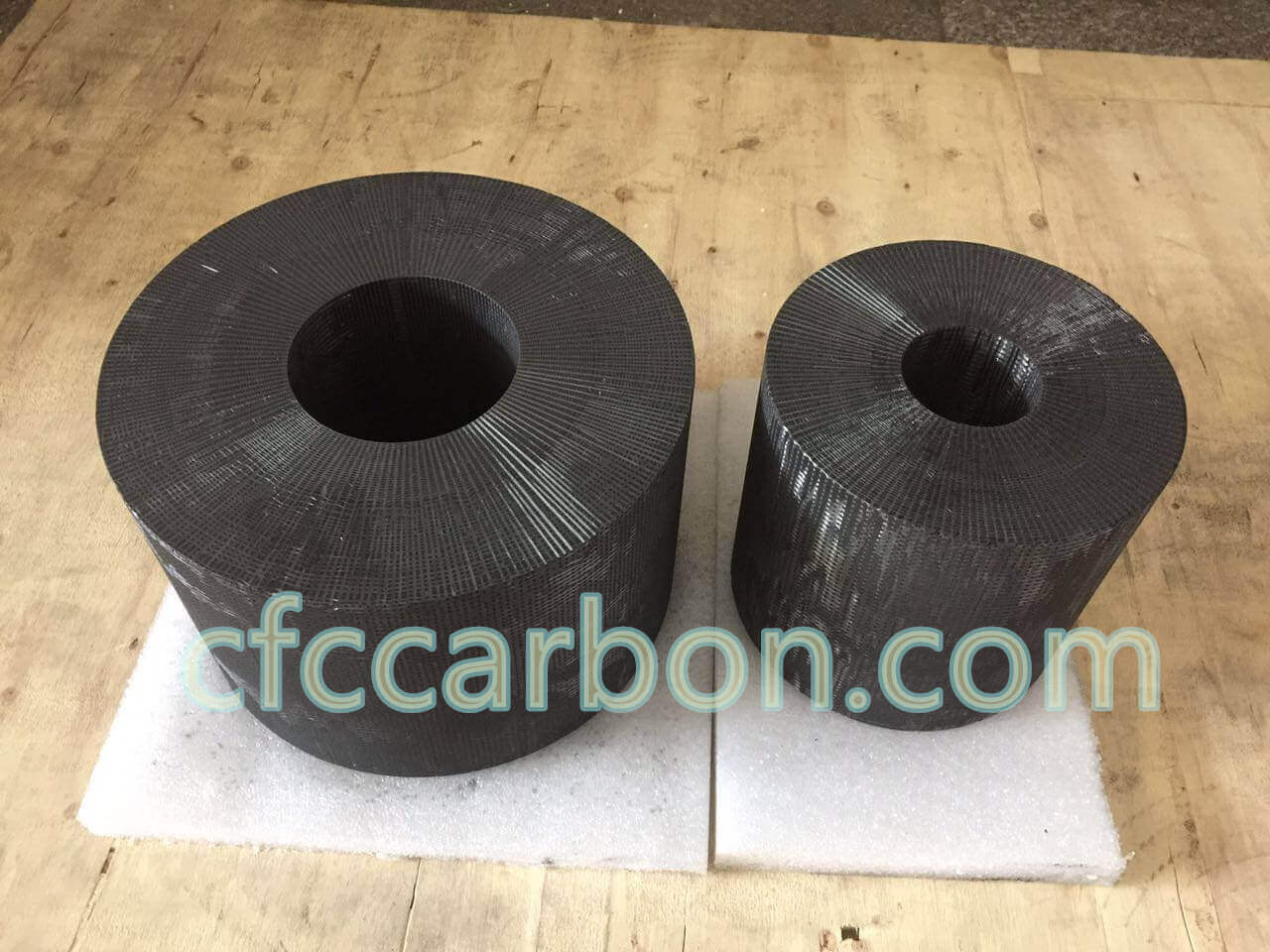

3D 4D Cylinders, Rings, structural diagram carbon fiber, composite, material mould rods China (1)

A 2023 case study by CFC Carbon revealed that 2D-wound C/C molds:

Reduced ceramic part defects by 52% compared to graphite.

Achieved 98% dimensional accuracy after 1,000 thermal cycles.

Lowered energy consumption by 18% due to faster heat transfer.

6. Sustainability & Cost Efficiency

While C/C molds have higher upfront costs, their longevity and precision reduce long-term expenses. For example, a single CFC Carbon mold can replace 6-8 graphite molds annually, cutting waste and downtime. Additionally, carbon fiber composites are 100% recyclable, aligning with circular economy goals.

7. Why Choose CFC Carbon?

As a leader in carbon composite technology, CFC Carbon provides:

ISO 9001-Certified Production: Rigorous quality control for consistency.

24/7 Technical Support: From design optimization to post-sale maintenance.

Global Logistics: Fast delivery to 50+ countries.

2025年5月1日星期四

Ablation rate comparison and Material Selection for C/C vs C/SiC

Title: Carbon-Carbon (C/C) vs. Silicon Carbide (C/SiC): A Comprehensive Guide to Ablation Resistance and Material Selection

Understanding Ablation Rates and High-Temperature Material Performance

3D 4D 5D Hoops, Loop, weaving, stucture, drawing, carbon fiber, carbon, composite, CFC, CC, manufacturer, China, (1)

In extreme environments such as aerospace, hypersonic vehicles, and re-entry systems, selecting the right ablation-resistant material is critical. Two leading candidates—carbon-carbon (C/C) and carbon-silicon carbide (C/SiC)—offer distinct advantages depending on temperature ranges and operational conditions. Below, we break down their ablation behaviors, structural properties, and optimal use cases.

1. What is Ablation Rate?

Ablation rate measures how quickly a material erodes under extreme heat and chemical reactions (e.g., oxidation). It is quantified by linear ablation rate (mm/s) and weight ablation rate (mg/s), critical metrics for evaluating thermal protection systems (TPS).

2. C/SiC vs. C/C: Key Differences in Ablation Resistance

Low to Moderate Temperatures (≤1600°C)

3D-xyz structure-carbon fiber composite material-CC-CFC

C/SiC Composites: Excel due to superior oxidation resistance. At 1600°C, their linear ablation rate (e.g., 0.068 mm/s for PIP-type) is lower than C/C.

C/C Materials: Begin oxidizing above 400°C but remain stable up to 1600°C with minimal mass loss.

Ultra-High Temperatures (2000°C+)

C/SiC Limitations: Above 2000°C, SiC decomposes into volatile SiO gas, causing severe non-uniform ablation and surface peeling (e.g., 0.012–0.023 mm/s at 2300°C).

C/C Superiority: Carbon fibers and matrix erode uniformly without catastrophic failure. Even at 3200°C, C/C maintains structural integrity in inert/vacuum environments.

3. C/SiC Subtypes: PIP vs. LSI Manufacturing

Two primary methods produce C/SiC composites:

LSI (Liquid Silicon Infiltration):

Reacts silicon with carbon to form SiC.

Lower SiC content (~50–70%), uneven distribution, and fiber damage reduce strength.

PIP (Polymer Infiltration and Pyrolysis):

Achieves higher SiC content (80%+) with uniform crystallinity.

Superior ablation resistance below 2300°C but underperforms LSI at extreme temperatures.

Ablation Test Data (2300°C):

| Type | Density (g/cm³) | Linear Rate (mm/s) | Weight Rate (mg/s) |

|---|---|---|---|

| PIP | 1.90–1.95 | 0.066–0.068 | 2.48–3.23 |

| LSI | 2.10–2.30 | 0.012–0.023 | 0.34–1.68 |

Conclusion: LSI outperforms PIP at ≥2300°C due to denser structure and lower porosity.

4. Temperature Limits in Different Environments

| Environment | C/SiC Stability | C/C Stability |

|---|---|---|

| Air | ≤400°C (no oxidation) | ≤1600°C (gradual oxidation) |

| Inert Gas | ≤2700°C (SiC gasifies) | ≤3200°C (intact fibers) |

| Vacuum | ≤2700°C (rapid gasification) | ≤3200°C (uniform ablation) |

5. Why C/C is the Ultimate Ablation-Resistant Material

C/C composites dominate in ultra-high-temperature applications (>2000°C) for three reasons:

Uniform Structure: Isotropic carbon fiber reinforcement ensures even stress distribution.

Predictable Erosion: No delamination or sudden failure—critical for re-entry vehicles.

Adaptability: Performs reliably in air, vacuum, and inert atmospheres.

6. CFCCARBON CO., LTD: Pioneering Advanced Ablation Solutions

For industries demanding unmatched thermal protection, CFCCARBON CO., LTD (www.cfccarbon.com) leads the market with cutting-edge C/C and C/SiC composites. Their expertise includes:

Tailored C/C Components: Optimized for rocket nozzles, brake systems, and nuclear reactors.

High-Precision C/SiC: Engineered via LSI/PIP for turbine blades and hypersonic TPS.

R&D Excellence: Custom solutions for temperatures up to 3200°C.

Why Choose CFCCARBON?

ISO-certified manufacturing with ultra-low porosity (<5%).

Global clientele in aerospace, energy, and defense.

Technical support for material selection and lifecycle management.

Visit www.cfccarbon.com to explore case studies and product specifications.

Final Recommendations

C/SiC: Ideal for thermal insulation below 2000°C (e.g., engine liners).

C/C: The gold standard for ablation-critical applications above 2000°C (e.g., rocket thrust chambers).

You can check the C/C vs C/SiC ablation resistant comparison sheet attached, or download it: https://www.cfccarbon.com/wp-content/uploads/2025/04/CFCvsC-SiCLSI-PIP-ablationmaterial-CFCCARBON-2025.pdf

For material specifications or partnership inquiries, contact CFCCARBON’s engineering team today.

related news /articles:

Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(6)-processing

Carbon Felt and C/SiC Material Manufacturer: Leading the Way in Advanced Composite Solutions

Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(1)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)