2025年3月29日星期六

3D 4D 5D carbon fiber composites structure and material manufacturer

What is “3D carbon fiber composite”

What is “4D carbon fiber composite” or “5D carbon fiber composite“?

Based on the existing information, the basic definition and characteristics of carbon fiber composites are as follows:

- Basic definition of carbon fiber composites

Carbon fiber composites are high-performance materials composed of carbon fiber and matrix materials such as resin, metal or ceramic, in which carbon fiber is used as a reinforcing phase, and the content is usually more than 90%. Carbon fiber itself has the characteristics of high strength, low density, and high temperature resistance. After being compounded with matrix materials, it can form a structural material with both lightweight and high performance.

2. Understanding of the “D” dimension

There is currently no unified standard for the definition of the “D” dimension in the scientific field, and there are different explanations in different research directions:

3D carbon fiber composites

Some materials understand “3D” as a three-dimensional structural design, which means optimizing the mechanical properties of materials in three-dimensional space by optimizing the weaving method of carbon fiber tows or the distribution of matrix materials. For example, by improving the 3D printing process, carbon fiber composites can have a more uniform mechanical distribution and higher impact resistance.

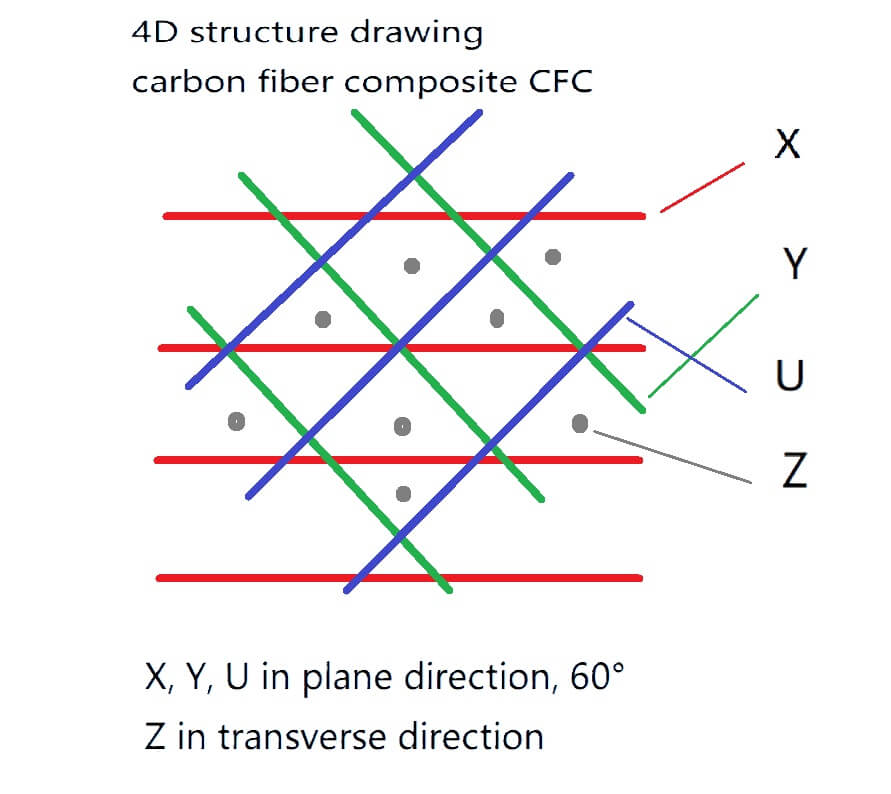

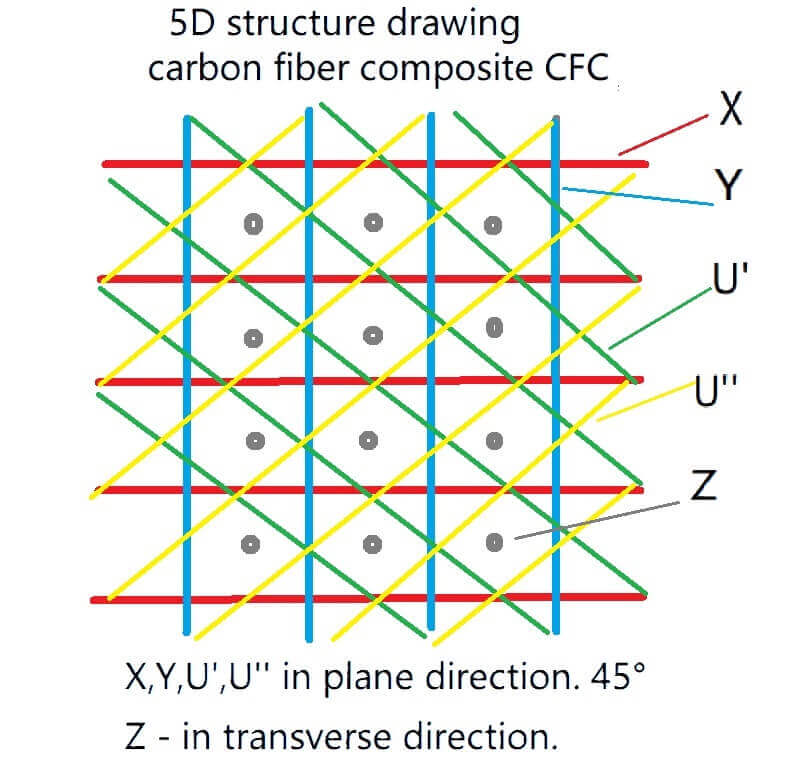

4D/5D carbon fiber composite materials

In these two types of materials, D represents the fiber direction! Rather than the three-dimensional spatial structure.

For example, 4D carbon fiber composites form 4 directions by adding a fiber direction on the plane direction, so we call it 4D carbon fiber composites;

5D carbon fiber composites form 5 directions by adding 2 fiber directions on the plane direction, so we call it 5D carbon fiber composites;

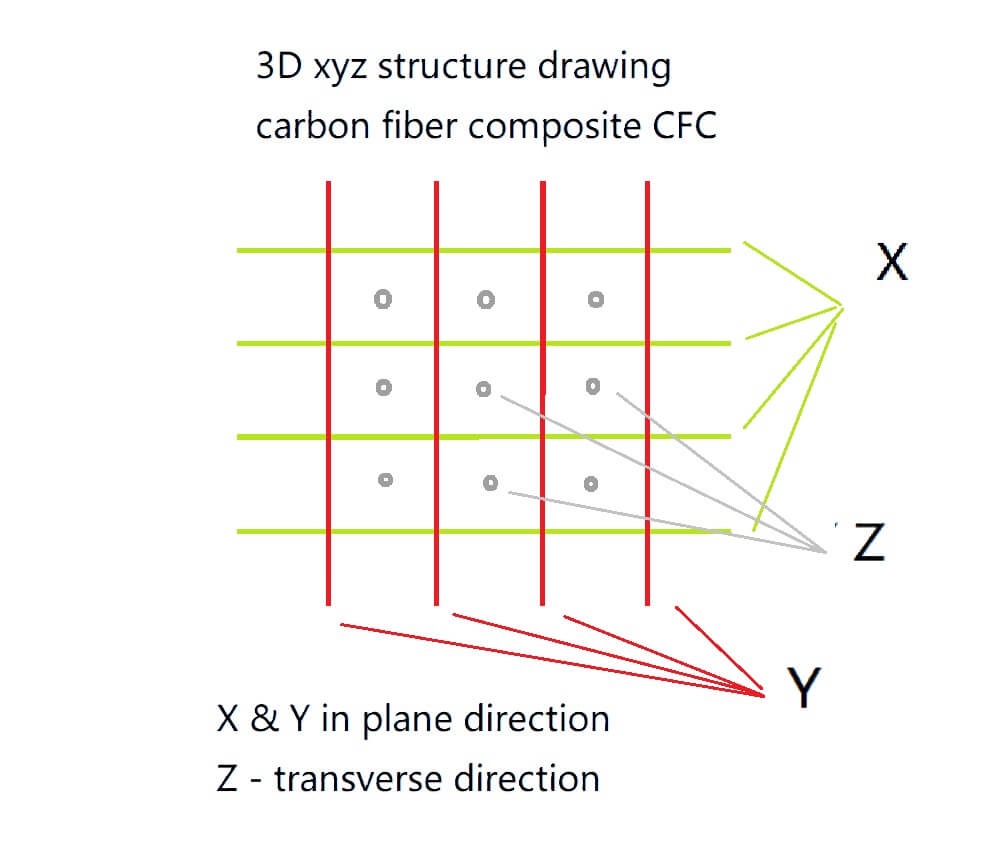

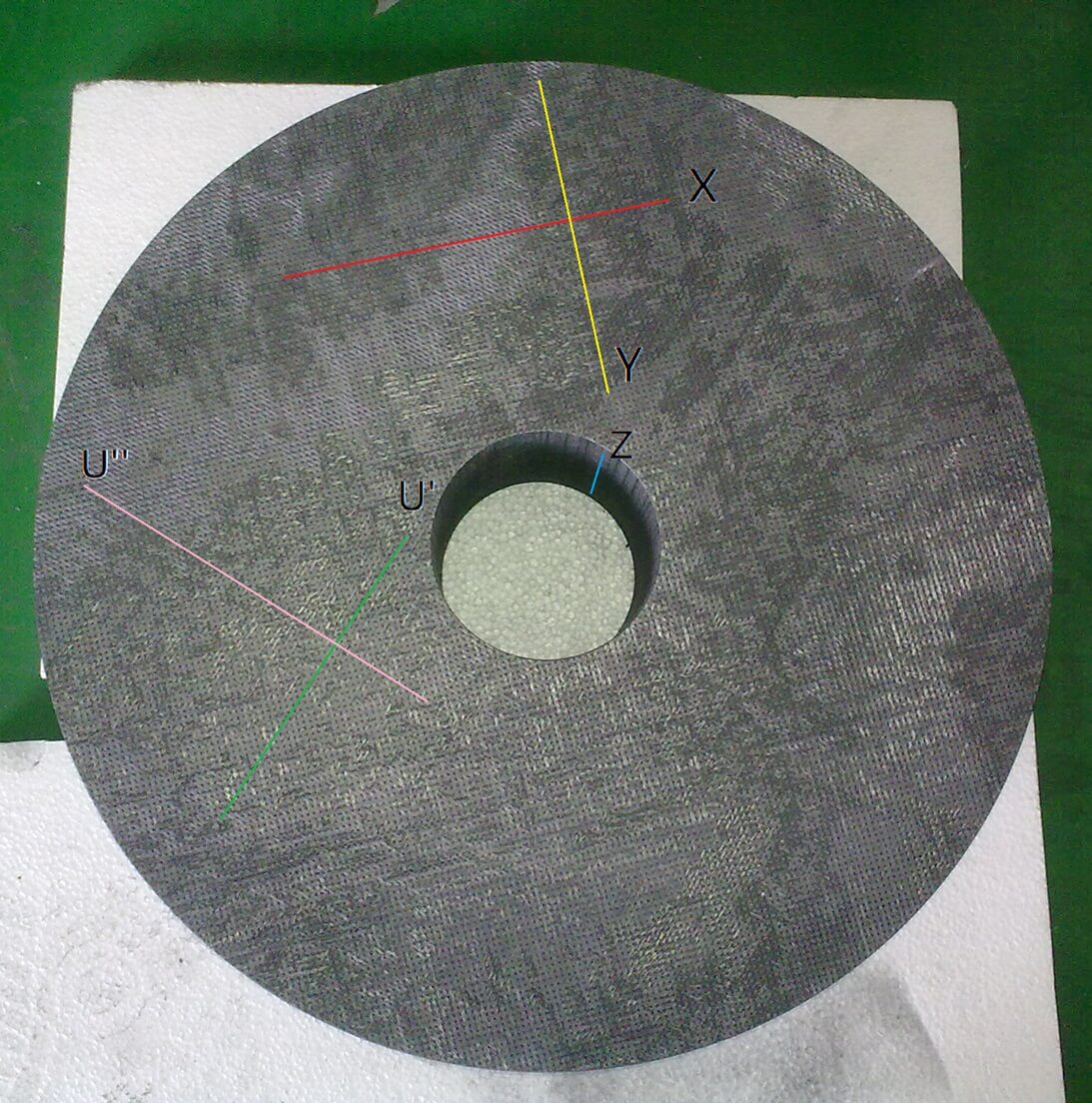

The following are the structural diagrams of 3D, 4D, and 5D carbon fiber composites, and the pictures of the corresponding products:

3D carbon fiber composite CFC structure drawing

3D-xyz structure-carbon fiber composite material-CC-CFC

3D orthogonal carbon fiber composite material

3D carbon composite material, manufacturer, China,

4D carbon fiber composite CFC structure drawing;

4D carbon fiber composite CFC Structural diagram;

4D carbon fiber composite CFC material, manufacturer in China

5D carbon fiber composite CFC structural diagram – drawing;

5D carbon fiber composite CFC Structural diagram;

What is 5D carbon fiber composite material?

5D carbon fiber composite structural diagram; 5D structural drawing.

5D carbon fiber composite CFC material

3. Comparison of application fields of 3D 4D 5D carbon fiber composites

Traditional carbon fiber composites Aerospace, automobile manufacturing, sports equipment, etc. Lightweight, high strength, corrosion resistance

3D carbon fiber composites Home decoration design, medical equipment, etc. Mechanical performance optimization, customized shape

4D/5D carbon fiber composites Smart materials, bionic structures, etc. Dynamic response, self-repairing function.

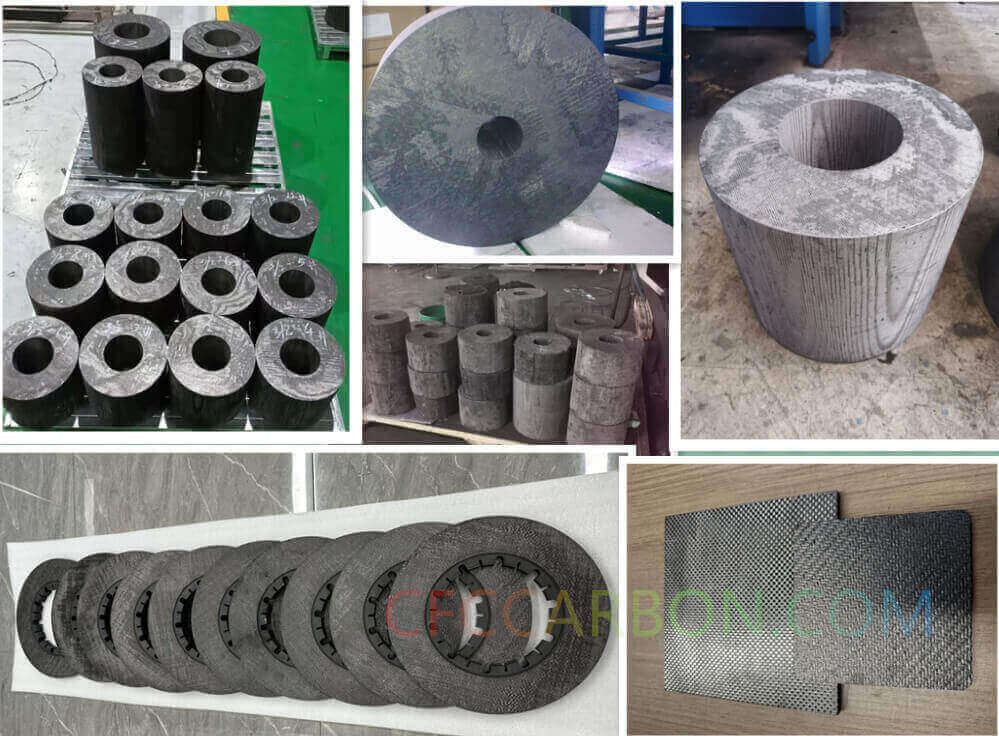

CFCCARBON is a manufacturer and exporter specializing in carbon fiber preforms, plates, and 3D 4D 5D carbon fiber composite materials. Our products have stable quality, excellent performance, reasonable price, and precise delivery time control. Over the years, we have won the trust and praise of customers from all over the world with excellent service.

If you want to know more about the structure, performance, price, product indicators, etc. of 3D 4D 5D carbon fiber composite materials, please contact us.

If you need more photos, material indicators, etc. of 3D 4D 5D carbon fiber composite materials, please don’t hesitate to ask us.

2025年3月23日星期日

3D Carbon fiber reinforced carbon composites material

Keywords: 3D carbon fiber composite, 3D carbon fiber composite material, 3D carbon fiber composite material, carbon fiber composite, 3D C/C, CFC, carbon carbon, carbon composite, material, manufacturer, China.

Carbon composites are high-performance materials formed by composite processes with carbon fiber or graphite fiber as reinforcement and pure carbon (such as resin carbon, deposited carbon) as matrix material. Its core features and applications are as follows:

- What is a carbon fiber composite:

3D carbon fiber composite material manufacturer factory -airplane brake disc plates sheets U L profiles-2D(6)

Carbon composites are composed of carbon fiber or graphite fiber as reinforcement phase and carbon matrix (such as resin carbon, deposited carbon) as matrix material, and belong to multiphase carbon-based composites.

if we use 3D carbon fiber preform, which is made by three-dimensional weaving method, then we can get a 3D carbon fiber composite material.

Microstructure of carbon fiber composites:

From a microscopic point of view, carbon composites are composed of four parts:

Carbon fiber/graphite fiber:

Reinforcement phase, providing high strength and modulus;

Matrix carbon: Transfer load to reinforcement phase;

Interface layer: Contact interface between carbon fiber and matrix carbon;

Porosity and microcracks: Affect material density and mechanical properties.

- Core performance of carbon fiber composites

High temperature performance of carbon fiber composites:

Can withstand high temperatures above 1650℃, with a maximum theoretical temperature of 2600℃, it is an ideal material for high temperature environments.

Mechanical properties of carbon fiber composite materials:

High strength and high modulus: 5-10 times higher than steel and 100 times higher than aluminum alloy;

Low density: The density is only 1/3-1/4 of steel and light weight;

Impact resistance and fracture toughness: It has both high strength and plasticity to avoid brittle fracture.

Other characteristics of carbon fiber composite materials:

Corrosion resistance: Strong chemical stability, suitable for corrosive environments such as acids and alkalis;

Low expansion coefficient: Small deformation when temperature changes, maintaining dimensional stability;

Excellent friction performance: Wear-resistant and anti-sliding.

- Application fields of carbon fiber composite materials

Aerospace:

Used for high-temperature components such as engine combustion chambers and turbine blades to improve fuel efficiency and life.

Energy field:

In scenes such as nuclear reactors and high-temperature furnace tubes, resist extreme thermal environments.

Automobile and industry:

Applied to high-performance brake systems, gears, etc., to reduce energy consumption and extend service life.

Other fields:

Including sports equipment (such as golf clubs), medical equipment, etc., taking advantage of its lightweight and high rigidity characteristics.

Carbon composites have become one of the most promising high-performance materials in the field of modern engineering due to their unique carbon-based composition and reinforcement mechanism, especially in high-temperature and high-strength scenarios.

What exactly is 3D carbon fiber composite material?

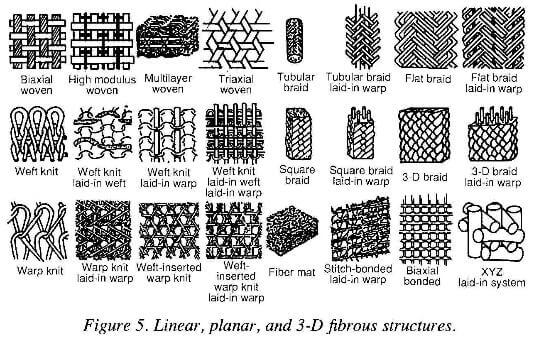

linear, planar, and 3D fibrous structures

- According to the different structures of carbon fiber woven into different structures, carbon fiber composite materials with different structures are formed. If the carbon fiber composite material is made by laying carbon cloth flat, it is a 2D material, mainly plates, profiles, etc.; if the carbon fiber composite material is made by three-dimensional weaving method, it is called 3D material. As shown in the structure diagram:

CFCCARBON is a manufacturer and exporter specializing in carbon fiber preforms, plates, and 3D carbon fiber composite materials. Our products have stable quality, excellent performance, reasonable price, and precise delivery time control. Over the years, we have won the trust and praise of customers from all over the world with excellent service.

If you want to know more about the structure, performance, price, product indicators, etc. of 3D carbon fiber composite materials, please contact us.

If you need more photos, material indicators, etc. of 3D carbon fiber composite materials, please don’t hesitate to ask us.

2025年3月21日星期五

Wet-molded integral Rayon graphite felt insulation barrel-crystal growing furnace

Wet-formed graphite felt is a graphite fiber reinforced material prepared by a wet process. It has the characteristics of high thermal conductivity, high temperature resistance, and corrosion resistance. It is mainly used in the following fields:

Main application areas:Insulation materials for single crystal silicon smelting furnaces

As a key material in the production of single crystal silicon, wet-formed graphite felt can effectively isolate high-temperature areas, reduce heat conduction, and improve process efficiency.

Insulation and heat insulation materials in various crystal growth furnaces…

more details, please check: https://www.cfccarbon.com/graphite-felt/wet-molded-integral-rayon-graphite-felt-insulation-barrel-crystal-growing-furnace.html

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)