China has long been a leader in global manufacturing, and in the field of green technology and environmental protection industries, it has also maintained a strong innovative force. In this regard, Chinese carbon fiber composite preform and products/material manufacturers have become an important force driving the industry’s development. In recent years, the widespread applications of Chinese carbon fiber composite materials in aerospace, automotive manufacturing, sports equipment, and other fields demonstrate their significant contribution to promoting sustainable development and energy conservation.

1. Innovative Technology Driving Industry Advancement

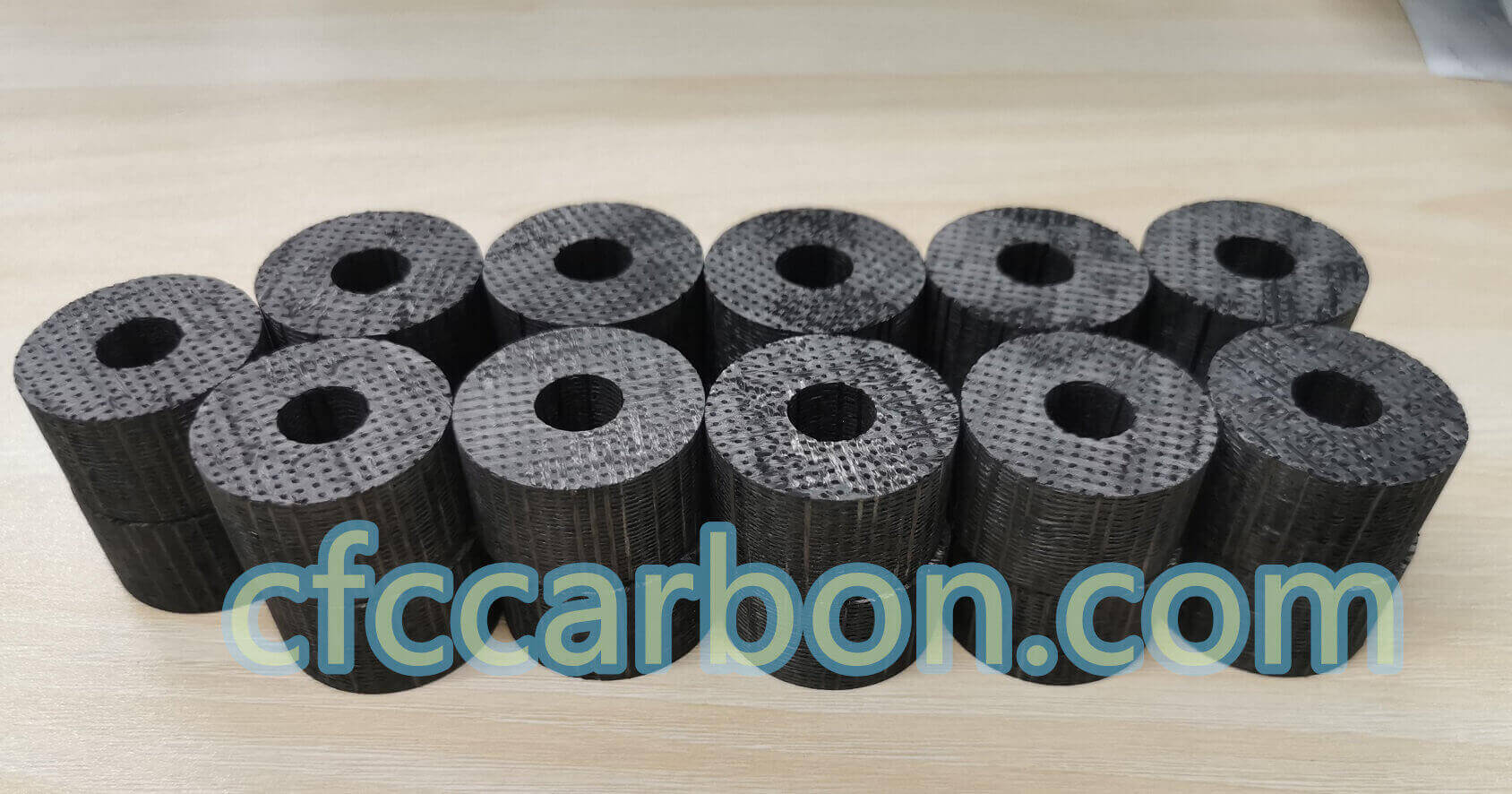

carbon fiber composite material manufacturer in China(1)

Chinese carbon fiber composite preform and products/material manufacturers are at the forefront of the carbon fiber composite materials industry, driven by continuous technological innovation. Through ongoing research and development in materials science, production processes, and design applications, they have not only improved the performance of carbon fiber composite materials but also substantially reduced production costs, enabling the wide-ranging application of these materials in various fields.

2. Promoting Industry Upgrading and Transformation

The continuous innovation and progress of Chinese carbon fiber composite preform and products/material manufacturers have driven the upgrading and transformation of related industries. In traditional manufacturing sectors, more enterprises are adopting carbon fiber composite materials to replace conventional materials, enhancing product performance and quality while reducing energy consumption and environmental emissions. This transformation has also elevated China’s position in the global carbon fiber composite materials market.

3. Green and Environmentally Friendly, Supporting Sustainable Development

As a lightweight and high-strength material, carbon fiber composites provide robust support for achieving sustainable development goals. By utilizing carbon fiber composites, the aerospace and automotive industries can reduce flight and driving energy consumption, lowering carbon dioxide emissions. Moreover, the use of carbon fiber composites can extend product lifespans and reduce resource waste, further promoting the development of a green circular economy.

4. Market Potential and International Cooperation

As one of the world’s largest manufacturing countries, China’s carbon fiber composite preform and products/material manufacturers have attracted international attention due to their market potential. Numerous international companies are seeking collaboration with Chinese manufacturers to jointly explore global markets by leveraging China’s advanced carbon fiber composite technology and production capabilities.

In the context of carbon reduction and sustainable development becoming a global consensus, Chinese carbon fiber composite preform and products/material manufacturers, with their green innovative technology and industry leadership, will continue to play a crucial role in promoting the application and industrial upgrading of carbon fiber composites. This not only advances the development of China’s carbon fiber composite materials industry but also contributes to the realization of global sustainable development goals.

CFCCARBON CO. LTD is a manufacturer of carbon fiber composite | C/C composite in china, with stable and reliable quality. Product range: 2D,2.5D,3D,4D carbon composite, with density from 1.40-1.95g/cm3, with CVD, CVI processing, or pitch based carbon composite. also, we produce carbon ceramic composite material and products.