1. Introduction: What Are Rigid Graphite Felt Boards for Energy Storage Applications?

Rigid graphite felt boards are high-performance insulation materials manufactured by compressing and graphitizing carbon fibers into semi-rigid panels. These boards exhibit exceptional thermal stability, low thermal conductivity, and high corrosion resistance, making them ideal for extreme-temperature environments. In energy storage applications, such as advanced battery systems, thermal energy storage (TES), and fuel cells, rigid graphite felts serve as critical components for heat insulation, electrodes, and structural supports. They enable efficient thermal management, reduce energy loss, and enhance the longevity of energy storage systems operating at temperatures up to 3000°C in inert atmospheres.

2. Product Classification: Tailored Solutions for Diverse Needs

CFCCARBON offers two primary types of rigid graphite felt boards, engineered to meet specific operational demands:

Long Fiber Rigid Graphite Felt Boards: Made from continuous rayon or PAN-based carbon fibers, these boards provide superior mechanical strength (flexural strength up to 0.9 MPa) and uniform thermal distribution. They are ideal for applications requiring repeated thermal cycling, such as solar thermal storage and aerospace power systems.

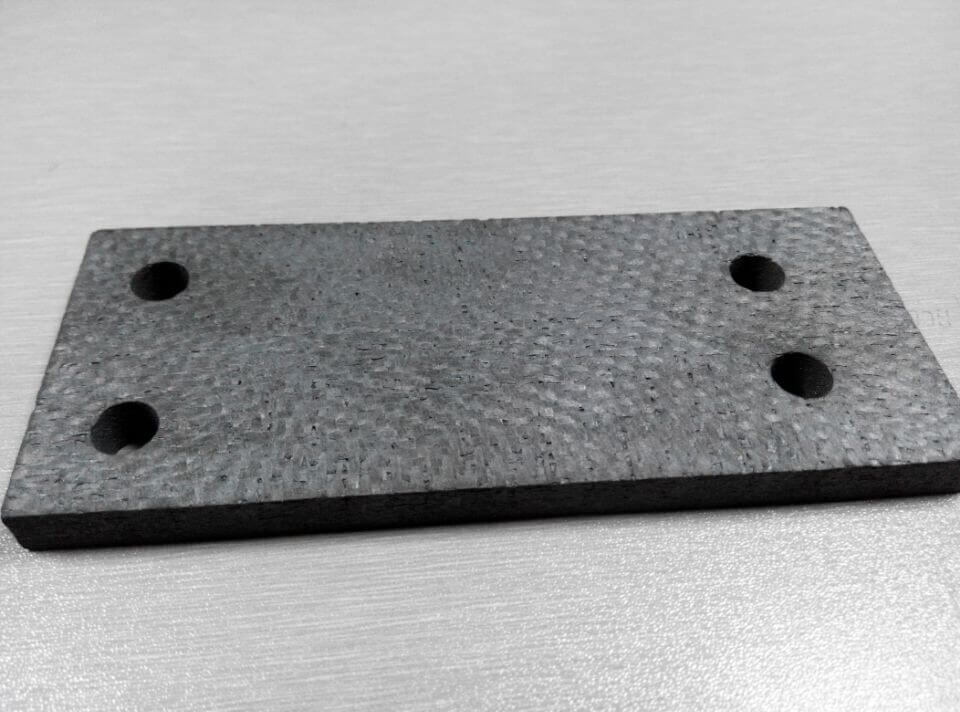

Short Fiber Molded Integral Rigid Graphite Felt Boards: Utilizing chopped carbon fibers bonded with resin, these boards feature enhanced dimensional stability and cost-effectiveness. They are commonly used in large-scale battery modules and industrial heat recuperators

3. Key Performance Metrics: Engineering Excellence

Rigid graphite felt boards from CFCCARBON adhere to stringent technical specifications, ensuring reliability in energy storage systems:

| Types | Laminated /Sandwich | short fiber /integral | ||

| Grade name | PRF-3 | RRF-3 | RRF-3W | RRF-3WP |

| Material type | PAN, long fiber, laminated. | Rayon, long fiber, laminated. | Rayon, short fiber, molded, integral | purified RRF-3W |

| Standard size /mm | 1800-1500-(20-200) | 1600-1260-460 | ||

| Carbon content | ≥99.9% | ≥99.9% | ≥99.92% | ≥99.99% |

| Ash content | 500PPM | 500PPM | ≤800PPM | ≤20PPM |

| Bulk density /g/cm3 | 0.20~0.30 | 0.18~0.22 | 0.17±0.01 | |

| Thermal conductivity (25°C) | <0.20W/m.K | <0.10W/m.K | <0.10W/m.K | |

| Thermal conductivity (1000°C) | <0.70W/m.K | <0.50W/m.K | <0.30W/m.K | |

| Compressive strength /Mpa | 1.2 | 0.9 | 0.7 | |

| Bending strength /Mpa | 1.5 | 1.1 | 0.9 | |

| Processing temperature | 2000 ℃ | 2000 ℃ | 2100 ℃ | |

| Application temperature (Vacuum/inert gases) | 1200~2500 ℃ | 1600~2500 ℃ | 1600~3000 ℃ | |

| Application temperature (Oxygen) | ≤400 ℃ | ≤450 ℃ | ≤400 ℃ | |

| Density for w.t calculation | 0.25g/cm3 | 0.20g/cm3 | 0.18g/cm3 | |

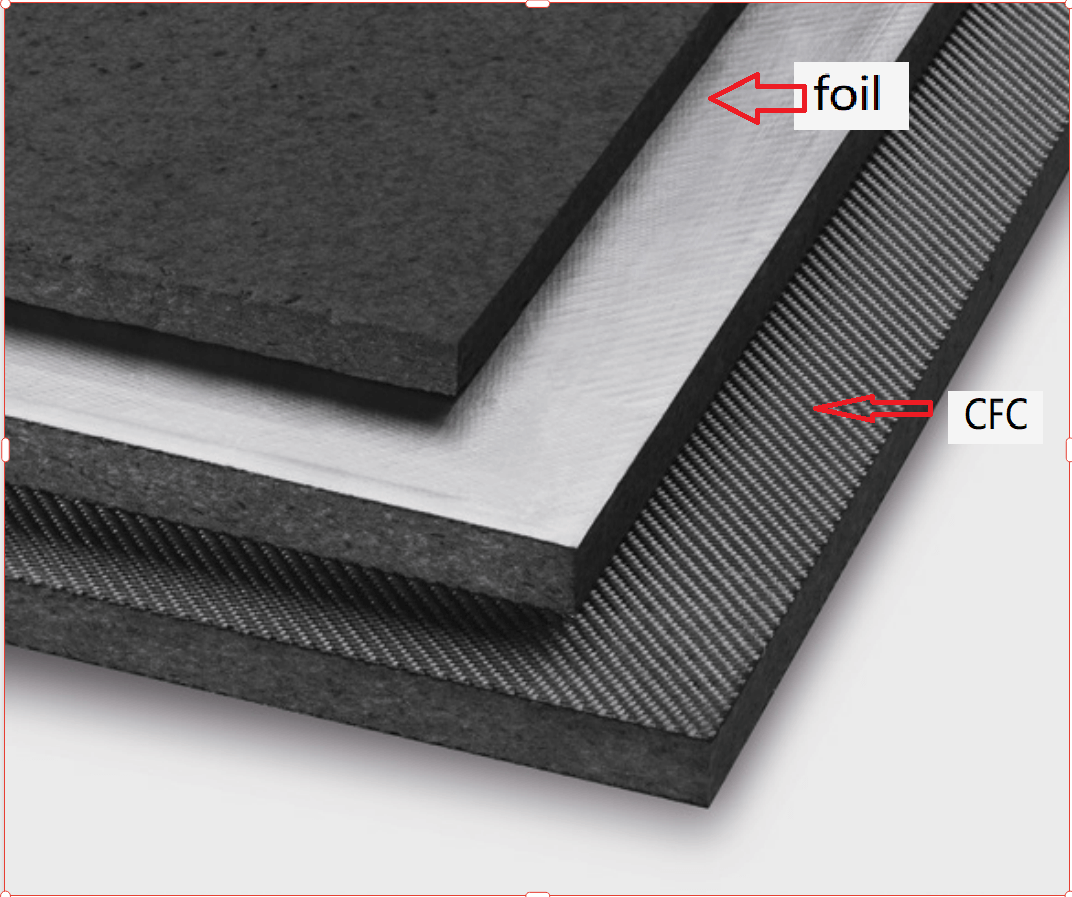

| Additional Process | with foil and or CFC, or coating, purification (≤20PPM) | with foil and or CFC, or coating, purification (≤20PPM) | with coating | |

4. Applications in Energy Storage: Driving Innovation

Thermal Energy Storage (TES): Rigid graphite boards insulate molten salt containers in concentrated solar power (CSP) plants, reducing heat loss by 30% and improving overall efficiency.

Fuel Cells: As gas diffusion layers (GDLs), they facilitate uniform reactant distribution and enhance conductivity in hydrogen fuel cells.

Advanced Batteries: In sodium-sulfur (Na-S) and lithium-ion batteries, the boards act as thermal barriers, mitigating thermal runaway risks

5. CFCCARBON’s Competitive Edge: Quality, Affordability, and Service

Cost Efficiency: Direct manufacturing capabilities enable 15–50% lower pricing than competitors without compromising quality.

Rapid Delivery: Standard orders fulfilled within 10–15 days, supported by streamlined logistics.

Customization: Boards can be tailored to unique dimensions (e.g., thickness: 10–120 mm, width: up to 1600 mm) and laminated with CFC or graphite foil for specific needs.

Free Samples: Pre-production samples available for client testing and validation.

6. Sustainability and Future Outlook

Rigid graphite felts contribute to sustainable energy solutions by:

Extending Equipment Lifespan: Resisting degradation under cyclic heating, they reduce replacement frequency.

Enabling Green Technologies: Support the growth of renewable energy systems like grid-scale storage and carbon-neutral

carbon graphite felt insulation soft hard rigid board short long fiber chopped material manufacturer factory China (13)

hydrogen production.

CFCCARBON is pioneering nano-enhanced felts doped with graphene to achieve 15% lower thermal conductivity and self-monitoring capabilities for next-generation smart grids

7. Visual and Pricing Overview

Product Images:

Image 1: Long fiber boards with uniform fibrous texture.

Image 2: Short fiber boards molded into complex shapes.

Pricing Table:

Small samples: Free;

Trial orders: Low prices and fast shipping;

Large orders: Discounted prices and short delivery times.

Semiconductor, rigid, graphite, felt, optical fiber, sapphire, silicon carbide, crystal growth, epitaxy, thermal equipment, Rayon, short fiber, SGL, third-generation, material, manufacturer, (3)

8. Conclusion: Partner with CFCCARBON for Cutting-Edge Solutions

Rigid graphite felt boards are indispensable to the future of energy storage, combining unparalleled thermal management with mechanical robustness. CFCCARBON’s expertise, competitive pricing, and commitment to innovation position them as the ideal partner for industries seeking reliable high-temperature materials.

Contact Us Today:

Email: potter@cfccarbon.com

Phone: +86-18910941489 (Marketing Center)

Explore Products: CFCCARBON Rigid Graphite Felt

Related news and articles:

Pan based rigid graphite felt

Rigid graphite felt parts, machined rigid graphite felt

Carbon & Graphite Insulation Boards | Rigid Graphite Felts manufacturer